Understanding spur gears with high efficiency

If it’s guaranteed that the spur gear will not have any defects, the only difference between a gear with lower efficiency and one of costs the same but still performs better, is how well a person gets to use them.

A detailed consideration of spur gears dildoes just that, and makes tea bag packing machines more effective, long-life equipments.

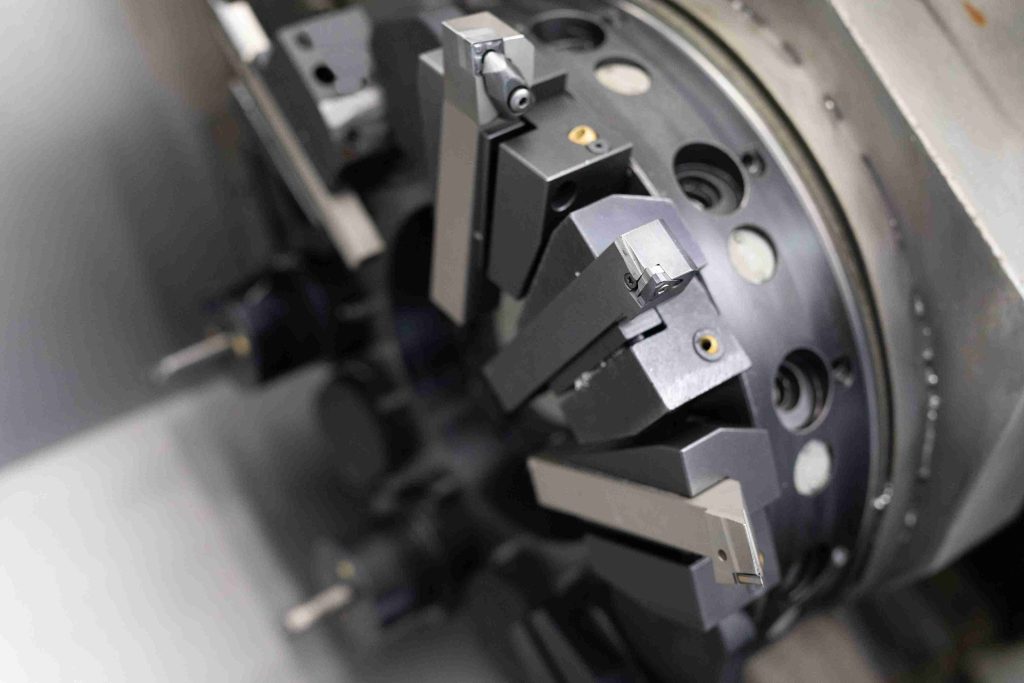

Key Components of spur gears with high efficiency

To understand the essence of spur gears with high efficiency, it’s essential to understand the key components that account for their superior performance. Below are the features which make such gears stand out:

| Component | Description |

|---|---|

| Tooth Profile | Optimized tooth profile makes power transmission more efficient |

| Material Quality | High quality materials extend wearable life. |

| Precise Machining | Accurate machining smooths running and results in minimal vibration |

| Lubricating System | An effective lubricating system means less frictional resistance, less heat generated. |

Advantages and Benefits of spur gears with high efficiency

The use of spur gears with high efficiency in Cap pressing machinery offers a number of advantages that improve overall performance. Some of these key benefits consist in more effective:

– Power Transmission Efficiency

– Noise Reduction

– Greater Wear Life / Durability

– Overall greater system reliability

Techniques for Optimizing Spur Gear Performance

To maximize the efficiency of spur gears with high performance, used in tea bag packing equipment, certain techniques can be employed. These techniques concentrate on the operation of the gears, and are aimed at increasing performance:

1. Gear Seating: Ensure equal and smooth seating of power transmission,

2. Regular Maintenance: Regular inspection and maintenance are essential to preventing faulty wearing parts. 4373770079

3. Lubricate Gears Regularly: Use appropriate lubricants. 67333396

4. Choosing High Quality Materials: Sustaining efforts to get only long-lasting materials. By these means, we will realize the full potential of spur gears with high performance in Cap pressing machines .

Explorations into the conveyor pressing machine principle

In this chapter, we are going to delve into the basic principles of cap pressing machinery, and look how we can optimize performance by using Highly efficient spur gears and cap pressing machines.

Basic Working Principles of Cap Pressing Machines

Cap pressing machinery runs by a set of principles to ensure efficient and accurate cap feeding. Here are the operational steps in how a cap pressing machine functions:

1. Loading Caps: The caps are loaded into the machine’s feed mechanism.

2. Alignment: Caps are accurately aligned for roiling.

3. Pressing Process: The hydraulic system pressurizes the caps onto our designated products.

4. Release: After completing the pressing, the caps are released out of the machine.

Use of Highly Efficient Spur Gears to Increase Performance

Highly efficient spur gears must play a role in maximizing the performance of cap pressing machinery. These gears make the transmission of power within the machine so smooth and precise that it operates consistently and reliably. By using high-quality spur gears, one can thus increase the total performance and longevity of cap pressing processes.

In conclusion, as for cap pressing machinery, after we understand the principles understand of cap pressing machinery; utilize high-speed spur gears; and implement good operating procedures, these are very necessary in order to bring maximum performance These guidelines should enable you to produce cap applications which are both high in quality and carry an optimum output.

Implementing Techniques for Optimizing Performance

When it comes to optimizing performance, in general, and especially in the realm of cap pressing machinery using highly efficient spur gears there are several essential techniques which can improve operations significantly. By putting the right strategies into operation, you can get the most out of what Robatherm offers in quality and quantity. Here are a few important techniques for reaching optimal performance with your cap pressing machine.

Techniques for Optimizing Performance

1. Regular Maintenance Schedule

One of the most fundamental techniques for optimizing the performance of your cap pressing machine is adhering to a regular maintenance schedule. By doing regular checks and lubricating key parts, replacing parts as they become old or damaged, you can ensure that your machinery operates at peak efficiency. This proactive approach to maintenance can avoid breakdowns and downtime, ultimately increasing productivity overall.

2. Proper Alignment of Spur Gears

Highly efficient spur gears are essential to the performance of cap pressing machinery. Proper alignment of these gears ensures smooth operation and minimum wear. Misaligned gears may increase friction, noise and reduce efficiency. By regularly checking and adjusting the alignments of your spur gears, you can optimize the performance of your machinery and extend its working life.

Comparison of Maintenance Techniques

| Maintenance Technique | Benefits |

|---|---|

| Regular Maintenance Schedule | – Decreases the risk of an unexpected breakdown |

| – Reduces equipment downtime for maintenance | |

| Proper Gear Alignment | – Reduces wear and tear on equipment |

| – Enhances system performance and efficiency |

Make sure you adhere closely to each practice,because modest mistakes may result in disastrous consequences for the end product. Therefore, to make full use of cap pressing machinery and to get the most from it that you can read these suggestions below:

Checklist for Performance Optimization In order to ensure that you are using performance-optimized production techniques and ensuring that your machines operate efficiently, use the following checklist as a reference: 1. Develop a regular maintenance schedule for your cap pressing machine. 2. Conduct a rigorous inspection of highly efficient spur gears for proper alignment. 3. Change lubricating medium in timely manner. 4. Keep meticulous maintenance records and a full set of performance metrics. 5. Train your workers at the best way to operate and take care of this equipment.

We trust that with these techniques and guidelines, the cap pressing machine’s performance should be improved slightly. NOTE: Be sure you will carry out correct maintenance of the bearings and gears on cap pressing machinery in order to achieve the highest level of life expectancy for your investent.

Best Practices for Effective Use of Cap Pressing Machines Cap pressing machines are an indispensable piece of equipment in the production process, especially when highly efficient spur gears are used. To ensure high levels of performance and efficiency, however, individual best practices need to be followed for using these machines. Below are several key techniques and tips which will help you make the most of your cap pressing machinery:

Proper Machine Setup Before any pressing operation is begun, be sure to set up your cap pressing machine properly. It is important that this includes calibrating the machine to the characteristics of caps being used and setting pressure gauges according as needed.

Regular Maintenance Checks

To make your cap pressing machine work efficiently and have a long lifespan, you need to give it regular inspections. This includes inspecting and cleaning all parts of the machine, such as the pressing plates and heating elements, to prevent problems that may affect its performance.

Optimal Temperature Control

Temperature control is crucial when using a cap pressing machine, especially for different kinds of caps and materials. It is necessary to adjust the temperature according to the different requirements of caps so as to achieve good adhesion and sealing effects.

Proper Alignment of Caps

When placing caps on the pressing machine, be sure to properly align them so that you can prevent any misalignment during the pressing process. Proper alignment will help ensure that pressure is distributed evenly over the entire surface and results are consistent.

Efficient Workflow Planning

Efficient workflow planning is vital to getting the most from your cap pressing machine. This includes putting the pressing process into an orderly routine so as to keep downtime at a minimum and output up to scratch.

Table: Cap Pressing Machine Comparison

| Features | Model A | Model B |

|---|---|---|

| Maximum Pressure | 1000 psi | 1200 psi |

| Heating Element Type | Ceramic | Stainless Steel |

| Capacity | 500 caps/hour | 700 caps/hour |

List: Tips for Effective Use of Cap Pressing Machines

- Always refer to the machine manual for specific instructions on operation and maintenance.

- Have regular training sessions for operators to see that they fully understand the purpose and use of the cap pressing machine.

- Closely monitor the pressing process and make adjustments as necessary for the best results.

- Keep spare parts and tools at hand for quick maintenance and repairs.

- Set up a preventive maintenance schedule so that there will never be sudden downtime.

By following these policies and procedures, you can enhance the performance and efficiency of your cap pressing machine, leading to improved production quality and output.

Article Summary

Summary:In summary, using highly efficient spur gears so as to optimize the performance of cap pressing machinery is an important measure in both productivity and the quality of products.By mastering these elements, you will be able to prolong the useful life of your cap pressing machinery and ensure high quality production. You can maximize the effectiveness and stability of your cap pressing machine if you keep in mind the following techniques for improving its performance:

- Proper Lubrication: Make sure that all moving parts including the spur gears, as are adequately lubricated so as to prevent friction and wear. In this way the life of your cap pressing machine will be extended indefinitely.

- Regular Maintenance: Schedule regular maintenance inspections. Replace gear wheels, bearings and belts at regular intervals in order to prevent unexpected mechanical failures whilst your equipment is functioning normally and putting out top-quality productionwork.

- Alignment & Calibration: Correctly align and calibrate the components of the cap pressing machine, especially the spur gears, thus ensuring that the machine moves correctly and that cap displacement is very accurate.4. The Growth of Spur Gear Manufacturing Machinery: If the machinery is not specifically geared to produce caps, then in order to get a high standards output of these complex products (especially when producing large quantities), then adjustments should be made in speed and torque setting.

Spur Gears with High Efficiency: A Comparison with Traditional Gears

| Criteria | Spur Gears with High Efficiency | Traditional Gears |

|---|---|---|

| Efficiency | High | Medium |

| Durability | Long service life | Ordinary |

| Precision | Accurate performance | Commonplace |

| Maintenance Requirements | Almost zero | Periodic |

Cap Pressing Machinery: A Checklist for More Effective Application

- Regular Inspection of Gear Teeth: Keep an eye on the gears’ teeth, to ensure they don’t wear down too much or get damaged–this will protect against future problems cropping up

- Lubrication Level Monitoring: Oil conditioning must be kept at the appropriate levels, in order to prevent overheating and early wear

- Sensor Calibration: Periodic calibration helps keep sensors finely tuned for accurate cap placement

- Operator Training: Teach your operators correct operating and maintenance techniques

If these techniques and good practices are incorporated into your operations, you can effectively utilize cap pressing machinery to its maximum proficiency with consistent high quality results regardless of what volume you have.

Conclusions

- By following the essential technique for optimizing performance through scrutiny of spur gear cap pressing machinery operation, it is possible to achieve greatly increased efficiency in manufacturing operations–offering more products at a lower cost to you.

- It is essential to do regular checks on the machinery and for those employing it, so as to lengthen the life and keep working reliably of the equipment–thereby ensuring that output is consistently high quality.

- To run the cap pressing machinery properly and efficiently and to train your operators in both its correct operation as well as best practices, can help to eliminate mistakes, periods of down time and effectively increase equipment overall performance.

- Taking care with operation as well as the purchase of high-grade spur gears which are installed in the machines helps to avoid problems before they arise–giving smooth operation.

- Regular monitoring of these performance indicators and fine tuning cap pressing machinery operation with the adjustments derived from this process of data analysis mean you can get its ultimate outperformance. In conclusion, mastering the essential technique for optimizing performance of spur gear cap pressing machinery is key to highly efficient production processes and fully making use of this essential item.