As advanced manufacturing technologies come together, they’re causing powerful shifts for industries all over the world. Industries are constantly looking for solutions that add efficiency, increase product quality, and decrease operating costs.

Among these innovations, the UV cylinder printer and the pyrolysis machine stand out as transformative technologies. Each machine addresses distinct industrial challenges yet collectively influences modern production landscapes.

Their functions have not only just been limited to a traditional application, but unprecedented possibilities in terms of customization, sustainability, and optimization of the operation. Seeing how these technologies work and how they could be connected will yield insight in how manufacturing and the use of resources will change in the future.

Advancements in Printing Technologies: The Role of the UV Cylinder Printer

Printing technology has evolved significantly over the last decade, and the UV cylinder printer is a prime example of how innovation has reshaped industrial operations. Instead of using standard ink types, it utilizes UV-curable inks that instantly cure when exposed to UV light. The result is an intense high-definition, durable and luminous printing on circular surfaces such as bottles, tumblers, cosmetics containers and industrial parts.

Manufacturers also have the benefit of superior precision and versatility and they can design dip and curve products going to the normally elaborate designs without degrading the quality. The

UV curing process doesn’t require the use of heat to dry, which saves energy and storage times. Furthermore, this technology facilitates direct-to-object printing, eliminating the need for conventional labels and improving efficiency in operations.

Another key advantage is the adaptability of UV cylinder printers to diverse materials, including glass, plastic, stainless steel, and coated metals. Whether you’re in cosmetics, food and beverage, pharmaceutical, or industrial packaging, this agility enables companies to enhance brand identity with high-end, bespoke design work.

Transforming Waste Management: How the Pyrolysis Machine Shapes Industrial Sustainability

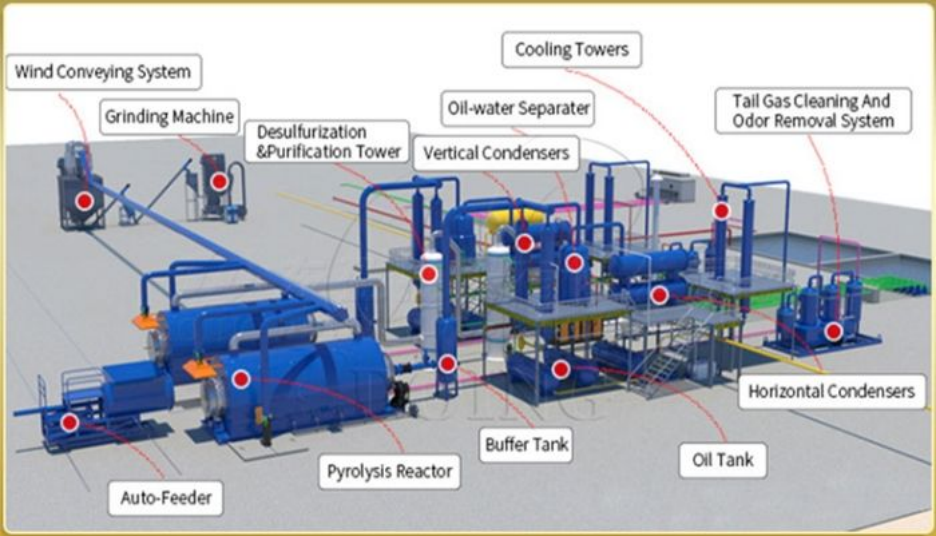

Industrial sustainability has become a strategic priority for businesses worldwide, and the pyrolysis machine plays a critical role in achieving these goals. This technology uses thermal decomposition under anaerobic conditions converting waste materials including plastics, rubber (tires) and biomass into useful by-products such as visco fuels, carbon black and gas.

Pyrolysis reduces harmful emissions as compared to incineration, making it an eco-friendly solution for managing industrial waste.

One of the best advantages of the pyrolysis technology is its ability to lower the landfill dependency. As the world’s waste production continues to grow, companies need new solutions that can not only more efficiently manage that waste, but also extract resources that have reuse potential. Pyrolysis machines address this challenge by transforming discarded materials into energy-rich outputs, contributing to a circular economy model where waste is repurposed rather than discarded.

It has been allowed traction by a number of industries including energy, packaging, automotive and chemical production industries. Not only do businesses using pyrolysis solutions follow environmental compliance laws, but they can also create new revenue streams from waste made into marketable goods. The integration of the waste to energy plant would result in an increase in resource efficiency, a decrease in operational costs and an increase in long term sustainability.

Bridging Innovation: How UV Cylinder Printers and Pyrolysis Machines Impact Modern Industries

While the UV cylinder printer and the pyrolysis machine serve distinct functions, their combined influence reflects broader trends driving industrial transformation. Both technologies support priority areas that manufacturers are trusting with: innovation, efficiency and environmental citizenship.

In consumer goods industries, UV cylinder printers help companies deliver premium packaging solutions with distinctive branding, enhancing shelf appeal and market competitiveness. At the same time, pyrolysis machines enable these manufacturers to manage production waste effectively, transforming discarded materials into useful by-products and minimizing environmental footprints.

Together, they embody a holistic approach to modern manufacturing that seamlessly blends design excellence with sustainable operations.

For example, UV printing packaging manufacturers are facing difficulties managing rejected or damaged printed material. What’s more, by incorporating pyrolysis systems, they can then reuse these materials for alternative fuels or other secondary products, creating a closed loop production process. This synergy streamlines manufacturing workflows, keeps material usage and volume at a maximum and ensures that operations are meeting global sustainability targets without sacrificing profitability.

Additionally, because regulatory structures on managing waste and control of emissions are tightening, and industries that incorporate both solutions will gain a competitive edge. UV printing enables reduced reliance on harmful solvents and traditional labels, lowering environmental impact, while pyrolysis machines provide a structured solution for handling production residues responsibly. Together they create a future forward-thinking industrial ecosystem of innovation and accountability.

Future Trends and Opportunities for Manufacturers and Businesses:

In the context of worldwide manufacturing trends, markets are changing quickly, influenced by rising consumer desires, sustainability issues, and technological advancement. The integration of UV cylinder printers and pyrolysis machines highlights several emerging trends influencing future growth strategies.

One of the important trends is mass customization, where consumers want products that are unique and customized for them without long production lead times. UV printing technology gives manufacturers a way to meet this task effectively – by producing bespoke designs with unprecedented fidelity. Customer Engagement and Brand Loyalty: With the growth of e-commerce, businesses that use personalized packaging will see increased engagement and brand loyalty.

Simultaneously, the rising emphasis on sustainable manufacturing practices positions pyrolysis machines as strategic assets for industrial players. The increasing regulations on waste disposal and carbon emissions implemented by governments and environmental organizations are forcing industries to turn to greener technologies. By transforming industrial waste into a source of usable energy, enterprises can limit environmental impact while increasing operational resilience.

The future will provide additional possibilities for combinations of digital manufacturing systems and environmental technologies. Production companies are able to use AI-powered design automation with UV printing for frictionless rapid prototyping or use advanced pyrolysis technologies to control waste at scale.

Conclusion:

Technological innovation continues to redefine modern manufacturing, with the UV cylinder printer and pyrolysis machine playing pivotal roles in shaping industrial progress. While the one change product design and customization revolutionizes, the other kicks in solving some of the most pertinent environmental concerns with waste-to-energy conversion.

Together, these technologies form a forward-looking strategy which perfectly fits at the crossroads of operational efficiency, sustainability and innovation. With this advanced solution, businesses can respond better to the changing needs of the consumers and remain conforming with the environmental regulations while ensuring long-term growth of business in competitive global markets.