The manufacturing sector has undergone massive transformation in the past ten years, thanks to the need of highly efficient, long lasting, and compact parts in the different fields. One area where technological precision and engineering innovation intersect is in the production of powder pumps.

In modern production environments, the integration of precision mould customization and powder pump technology has redefined how these devices function and how efficiently they deliver results.

This article explores how professional precision mould parts customization processing impacts powder pump manufacturing, enhances operational performance, and drives innovation in product design and efficiency.

The Growing Role of Professional Precision Mould Parts Customization Processing:

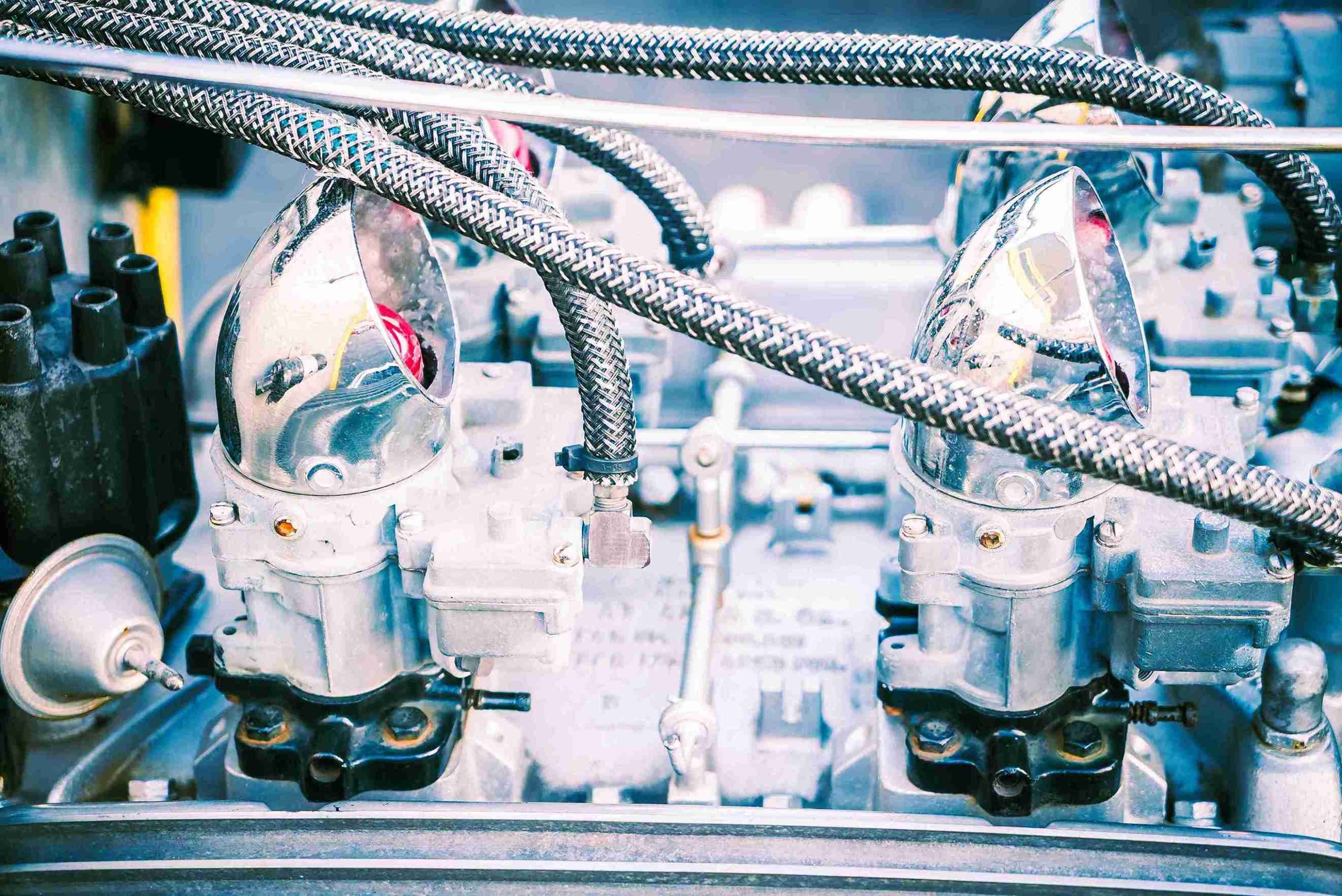

Professional precision mould parts customization processing focuses on creating moulded components with extremely tight tolerances, ensuring consistent performance and durability even in demanding environments. It utilises leading edge manufacturing technologies like CNC machining, EDM (electrical discharge machining), high-speed milling, and surface finishing to provide mould parts with extremely high accuracy.

For powder pump production, these customized mould parts play a vital role in determining the efficiency and reliability of the final product. Powder pumps require components like impellers, seals, nozzles, and housing structures to be manufactured with extreme precision, as even slight deviations can result in inconsistent powder flow or operational inefficiencies.

Modern customization techniques allow manufacturers to:

- Achieve High Dimensional Accuracy: Tolerances as fine as microns ensure each part perfectly aligns with its assembly counterparts, reducing friction and leakage.

- Utilize High-Performance Materials: The integration of stainless steel, engineering plastics, and corrosion-resistant alloys ensures long-lasting mould components.

- Support Complex Geometries: Innovative moulding techniques allow for intricate shapes, thin walls, and micro-features essential for compact powder pumps.

- Accelerate Product Development: Advanced prototyping capabilities enable faster design iterations and optimized final production.

By integrating these techniques into powder pump production, manufacturers ensure the final product meets strict standards of performance, safety, and efficiency.

Importance of Precision in Powder Pump Manufacturing:

Powder pumps are extensively utilized in industries such as pharmaceuticals, cosmetics, food processing, chemical engineering, and additive manufacturing. They are primarily used to transport, dose, or spray powdered materials in a consistent and accurate manner. To attain this degree of accuracy, these pumps use extremely specialized parts that can work harmoniously in different circumstances.

Customized mould parts play a crucial role in enhancing the overall performance of powder pumps in several key areas.

First, flow consistency is a must in predictable dosing. Impellers and flow channels are precision-moulded to help ensure uniform particle delivery by restraining turbulence, and thus reduce the possibility of clogs or inconsistencies. Mould quality also has a huge impact on durability and reliability.

Since powder pumps often process abrasive or chemically sensitive materials, the use of corrosion-resistant moulded components helps extend the operational lifespan of the pump while maintaining efficiency during long-term use.

Another important factor is leak prevention especially in such industries as pharmaceutical and food manufacturing where quality control and hygiene are of the essence. Professionally modified seals and casings will help to avoid the risk of powder leakage. Furthermore, energy efficiency can be enhanced by using well tailored components of the mould which minimizes internal friction, and enables the pump to operate with less energy consumption, but with constant output.

How Customization Drives Innovation in Powder Pump Technology?

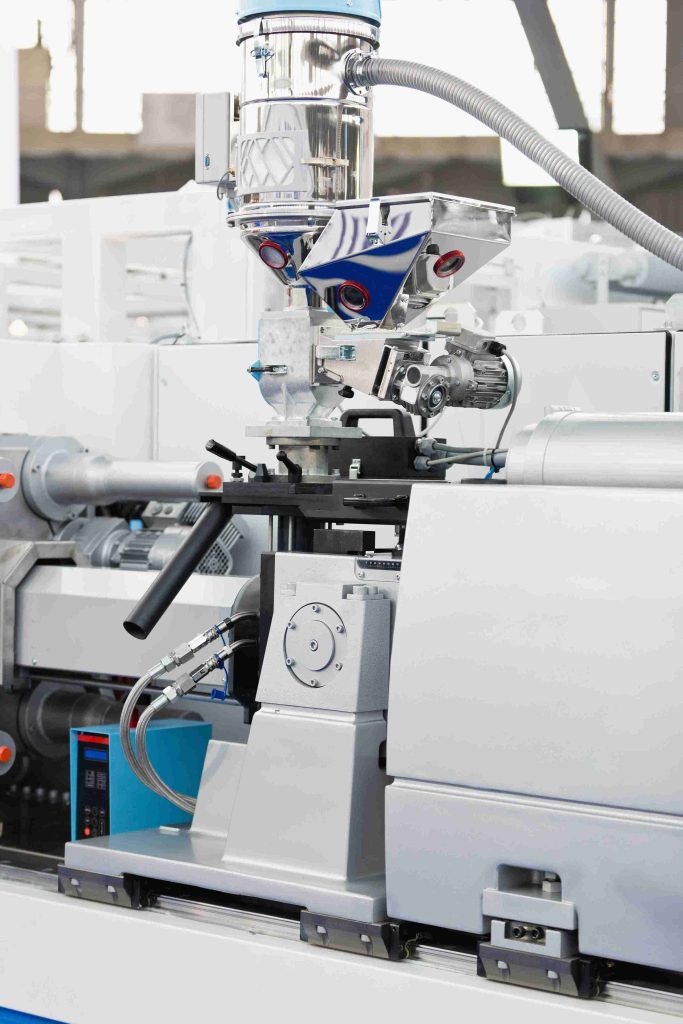

As industries continue to evolve, powder pump designs are becoming increasingly application-specific, pushing manufacturers to develop more tailored and adaptive solutions. Customization of professional precision mould parts is an essential part of this process, ensuring that it is possible to respond to new functional needs promptly without losing performance or reliability.

One of the areas of improvement is incorporation of sophisticated materials. Modern powder pumps must handle a wide variety of substances—from pharmaceutical excipients to highly abrasive industrial powders. Manufacturers have the ability to use high-grade stainless steel, PTFE or advanced engineering polymers in the pump parts by means of customized mould processing.

This makes it compatible with a wide range of powder properties, as well as improving the chemical resistance and mechanical resilience.

Another trend shaping powder pump design is the miniaturization of components. The need to have smaller and high-efficiency pumps in wearable medical devices, portable food processing units, and laboratory equipment has been increasing. Accuracy mould customization allows the production of micro-scale components, thus pumps can be smaller without compromising performance or dosing accuracy.

Powder Pumps in Specialized Applications:

The integration of customized mould parts has significantly broadened the application range of powder pumps across a wide variety of industries, enabling more precise, efficient, and reliable performance tailored to specific operational needs.

In the pharmaceutical industry, powder pumps play a critical role in ensuring accurate dosing of active ingredients and excipients, particularly in tablet production and inhalation therapies. Customized parts also contribute to high-hygiene standards and dosing accuracy that is vital to patient-safety and regulatory compliance.

In the cosmetics industry, accurate dispensing of powder ingredients is crucial to the makeup foundations, dry shampoos, and skin care products. Custom moulded parts ensure even flow and dispensing, improving the quality of the product as well as the user experience.

Within food processing, powder pumps are used for the controlled dispensing of ingredients, flavorings, and nutritional supplements along production lines. Customization will guarantee food safety by reducing the risk of contamination and making it compatible with different food-grade material.

In additive manufacturing, particularly in 3D printing, powder pumps must handle fine metal powders and composite materials with high accuracy. Custom mould parts facilitate the precise transport and dosing of the layer-by-layer process, and, thus, contribute to print quality and materials efficiency.

For industrial applications, such as those in chemical engineering, mining, and construction, powder pumps are tasked with transferring highly abrasive or reactive materials. With customized parts, durability, corrosion, and performance in harsh conditions are enhanced.

Across all these sectors, the customization of mould parts ensures that powder pumps operate not only with optimal efficiency and safety but also in full compliance with the rigorous standards and regulations specific to each industry.

Conclusion:

Professional precision mould parts customization processing has become integral to the development and optimization of powder pumps. By incorporating superior moulding technologies with high-performance materials, manufacturers are able to create components that not just assure precision, durability, and flexibility in a broad scope of applications.

Whether it is pharmaceuticals and cosmetics, industrial and additive manufacturing, precision customization increases efficiency in operations and boosts innovation in pump technology.