The world manufacturing industry is changing at an alarming rate, fuelled by the technology and the increase in the demands of the industry. Some of the new developments are precision moulding and chemical packaging solutions that have attracted a lot of attention. Industries need packaging techniques that maintain the integrity, safety and efficiency of their products in various applications.

This becomes especially relevant when considering modern aluminum foil container mold technologies and their role in safely storing sensitive compounds such as hydrogen peroxide emulsions.

Understanding how these two distinct areas connect highlights the importance of innovative manufacturing practices in addressing cross-industry challenges.

Advancements in Aluminum Foil Container Mould Technology:

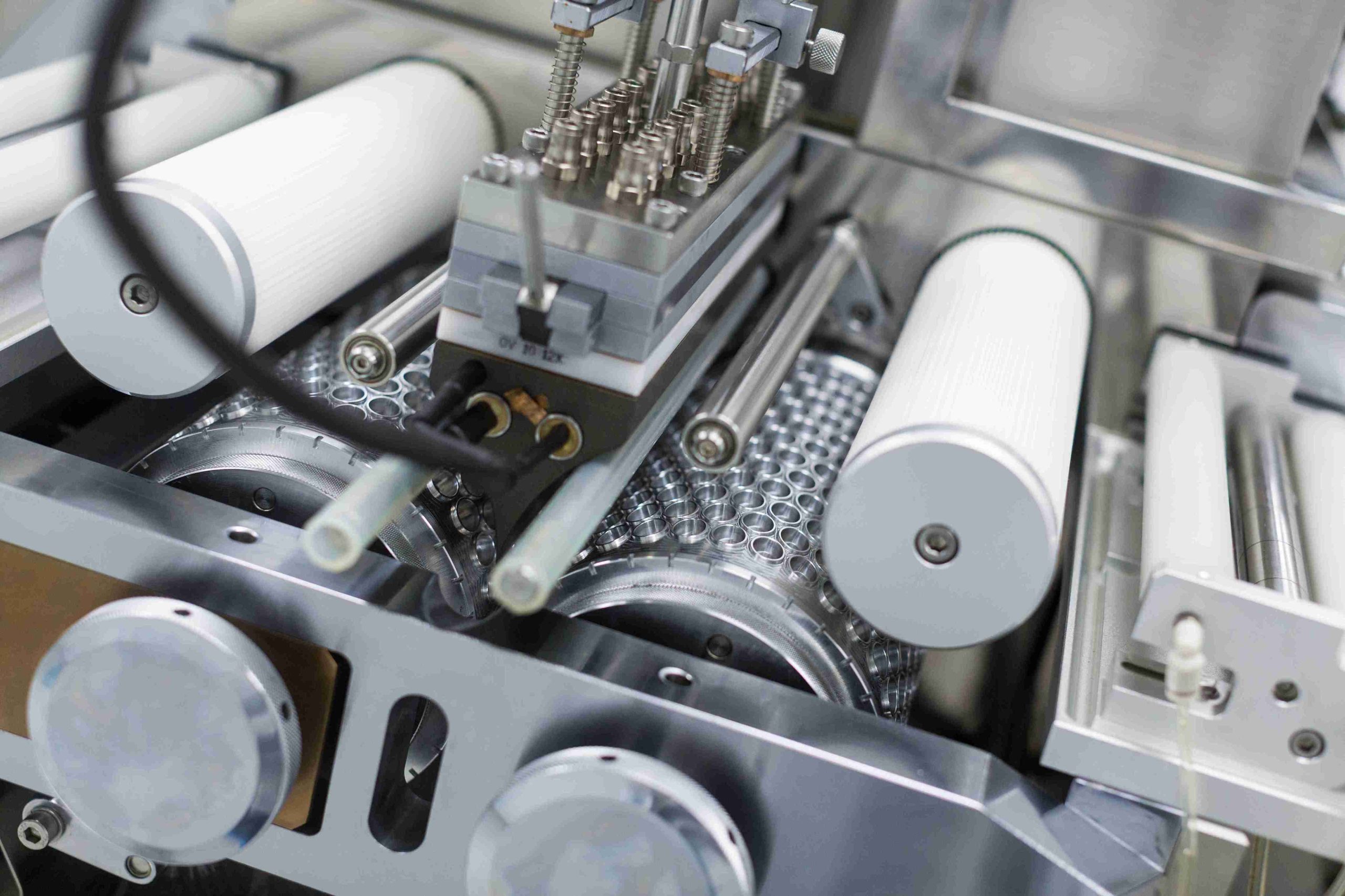

Aluminum foil container moulds have become central to the modern packaging industry, supporting multiple sectors, including food, pharmaceuticals, and chemical processing. These molds are precision engineered to address the growing need to have lightweight, durable and high-performance packaging. Manufacturers have been using computerized moulding systems that produce faster results at a time and also ensure uniformity in size and strength.

The increased demand of hygienic and trustworthy packaging has motivated the successive upgrades in the materials of moulds and designs. Aluminum foil container molds of new generation are created on the basis of high-grade alloys and the latest machining technologies. These innovations guarantee a higher compatibility with other packaging requirements, especially where high temperature fluctuations and reactivity with chemicals are required.

The aluminum foil containers offer a protective shield against the outside contaminants in industries where protection and safety of chemical substances is of paramount importance e.g. food sterilization and pharmaceutical production. Good-quality moulds would allow manufacturers to develop accurate packaging products that have minimal leakage and degradation.

Such technological advancement has made aluminum foil moulding a major contributor to consumer safety and industrial efficiency.

Hydrogen Peroxide Emulsion and Its Diverse Applications:

Hydrogen peroxide emulsions are widely used across healthcare, food processing, and chemical industries due to their strong oxidizing properties. Such emulsions are commonly produced by dispersion of hydrogen peroxide in stabilized formulations that allow the activity to be controlled and the performance to be improved.

Their special composition allows them to be used in sterilizing medical equipment, sterilizing food packaging surfaces and in treating industrial waste water.

Nonetheless, the reactivity of hydrogen peroxide is high, so it has to be handled and stored in special conditions. The compound may decompose without proper containment, resulting in a loss of effectiveness or in safety hazards in some cases. Here the quality of packaging becomes important. Containers should avoid corrosion, allow no penetration of light, and must have an airtight seal to ensure stability of chemicals.

Hydrogen peroxide emulsions also play a significant role in pharmaceutical and cosmetic formulations, where consistent concentration and stability are vital. Due to the rise in the industries, the need to have safe, efficient and reliable storage solutions is increasing and, therefore, there is an increased dependence on advanced packaging technologies that would be able to suit the specific properties of the compound.

The linking of Packaging Mould innovations with Chemical Safety:

Chemical-sensitive compounds like hydrogen peroxide emulsions pose significant challenges in packaging design. Chemical stability and safe handling have necessitated the development of specialized containers by manufacturers who have developed moulding solutions that are advanced. High-quality aluminum foil container moulds play a vital role in producing containers that meet these stringent requirements.

Aluminum as a packaging material has good barrier properties against moisture, light, and oxygen, which makes it ideal to store reactive materials. Advanced moulds enable manufacturers to produce containers with high tolerances, which results in a tight seal and controlled thickness to reduce the risk of contamination. Moreover, foil containers are light and non-corrosive and thus applicable in packaging chemicals that need extended storage in a controlled environment.

For hydrogen peroxide emulsions, which are highly sensitive to environmental factors, such packaging offers extended shelf life and improved safety during transportation. With an integration of high-end moulding technologies and chemical compatibility research, manufacturers are able to develop solutions to industry specific requirements. The system will lead to less wastage, efficiency of operations, and adherence to safety regulations.

Future Trends in Packaging and Chemical Integration:

The interconnectedness of industries will keep on increasing and so will the need to have packaging solutions that can accommodate the cross-industry demands. The requirement of precision-engineered moulds is also escalating to other sectors besides the traditional food and beverage packaging industry as it is also affecting chemical storage and drug manufacturing.

Future trends suggest that manufacturers will focus on developing aluminum foil container molds capable of supporting more complex applications, including highly sensitive formulations like hydrogen peroxide emulsions.

Smart manufacturing and automation technologies are likely to contribute to the development of molds as well. Computer-aided simulations will enable companies to foresee how different materials can react with the reactive compounds, which will result in optimal packaging solutions. Besides, new surface treatment and coating of aluminum containers are under investigation to increase chemical resistance without compromising lightweight qualities.

Another active trend is the incorporation of digital monitoring systems into packaging. Smart packaging alternatives can consist of indicators that sense temperature changes, exposure to light, or chemical breakdown. For substances like hydrogen peroxide emulsions, these innovations will help maintain quality control throughout the supply chain.

Conclusion:

The connection between packaging technologies and chemical safety has gained more importance in industries. Precision-engineered aluminum foil container moulds have transformed how manufacturers design secure, efficient, and versatile packaging solutions. At the same time, the growing applications of hydrogen peroxide emulsions in healthcare, food safety, and industrial processes highlight the need for reliable containment systems.

The future of packaging will therefore be synergized between the advanced moulding technologies and the chemical handling requirements as manufacturing continues to evolve. Businesses that invest in innovation will be in a better position to address complex requirements, guarantee the integrity of the product, operational efficiency, and consumer safety. This continuous integration demonstrates the importance of precision packaging to the advancement of technology in various industries.