Basic Understanding of Exterior and interior aluminum veneer

When it comes to exterior and interior aluminum veneer, the ins and outs of this medium are critical. Aluminum veneer is a very malleable cladding material that can be used just as well on the indoors and outdoors. Let us delve into the characteristics and uses of exterior and interior aluminum veneer to imagine how this school of craftsmanship contributes to construction today.

Characteristics of Exterior and Interior Aluminum Veneer

| Characteristic | Description |

|---|---|

| Durability | Aluminum veneer, both indoors and outdoors, has proven to be able to withstand extreme weather conditions. |

| Lightness | Being lightweight, exterior/interior aluminum veneer is handy in construction, easy to transport and assemble, and contributes to cutting production time. |

| Versatility | Its wide range of possible designs makes metal veneer a popular choice in architecture and design. |

Uses of Exterior and Interior Aluminum Veneer

| Application | Description |

|---|---|

| Exterior Cladding | Exterior aluminum veneer, a common expression behind one’s carefully crafted building, is used as cladding for both the construction itself and its blend into its environment. |

| Interior Finishes | Interior aluminum veneer gives the modern touch to interior space, providing an air of simple elegance and only the most modern feel. |

In modern aluminum veneer production, the role of Air-operated diaphragm pumps cannot be understated. These pumps work with exterior and interior aluminum veneer at all stages, from the initial manufacturing of aluminum alloy to the accurate, efficient application of all coatings and finishes. By understanding the interaction of these parts, manufacturers can attain the exquisitely perfect results they desire for aluminum veneer production.

By understanding its properties and applications, as well as the contribution of Air-operated diaphragm pumps , you can understand the importance of exterior and interior aluminum veneer in producing solid, good-looking buildings.

By using air-operated diaphragm pumps, efficiency and precision are guaranteed in every stage of aluminum veneer production. The role of these pumps is not just limited to moving adhesives from one place to another, they are also a crucial tool for spraying coatings on aluminum surfaces. To find out more about the importance of air-operated diaphragm pumps in the production process, keep reading these pages.

Greater Workflow and Precision Air-operated diaphragm pumps are known for their consistent flow rates, making them ideal for applications requiring an accurate distribution of material. By using these pumps one can ensure that both the exterior and interior veneers of aluminum are consistently covered in exactly the same thickness, creating a high-quality finish.

Used with a wide range of materials Perhaps the biggest attraction of air-operated diaphragm pumps is the wide array of materials they can handle. In a single pump unit suppliers can switch between adhesives, sealants and coatings, cutting down on unproductive changes-over between batches and driving up general efficiency for everybody involved.

List: Improvements to Air-Operated Diaphragm Pumps for Aluminum Veneer Production

1 Consistency in material distribution ensures that the thickness of paint is kept constant right down to each point on the veneer.

2 Channeling many materials through one pump reduces the number of pump units required – a bonus for manufacturers.

3 Self-priming capability and dry run are advantages of the air-operated diaphragm pump.

4 Lower maintenance needs than traditional pumps.

Key Components of High-Efficiency Air-Operated Diaphragm Pumps

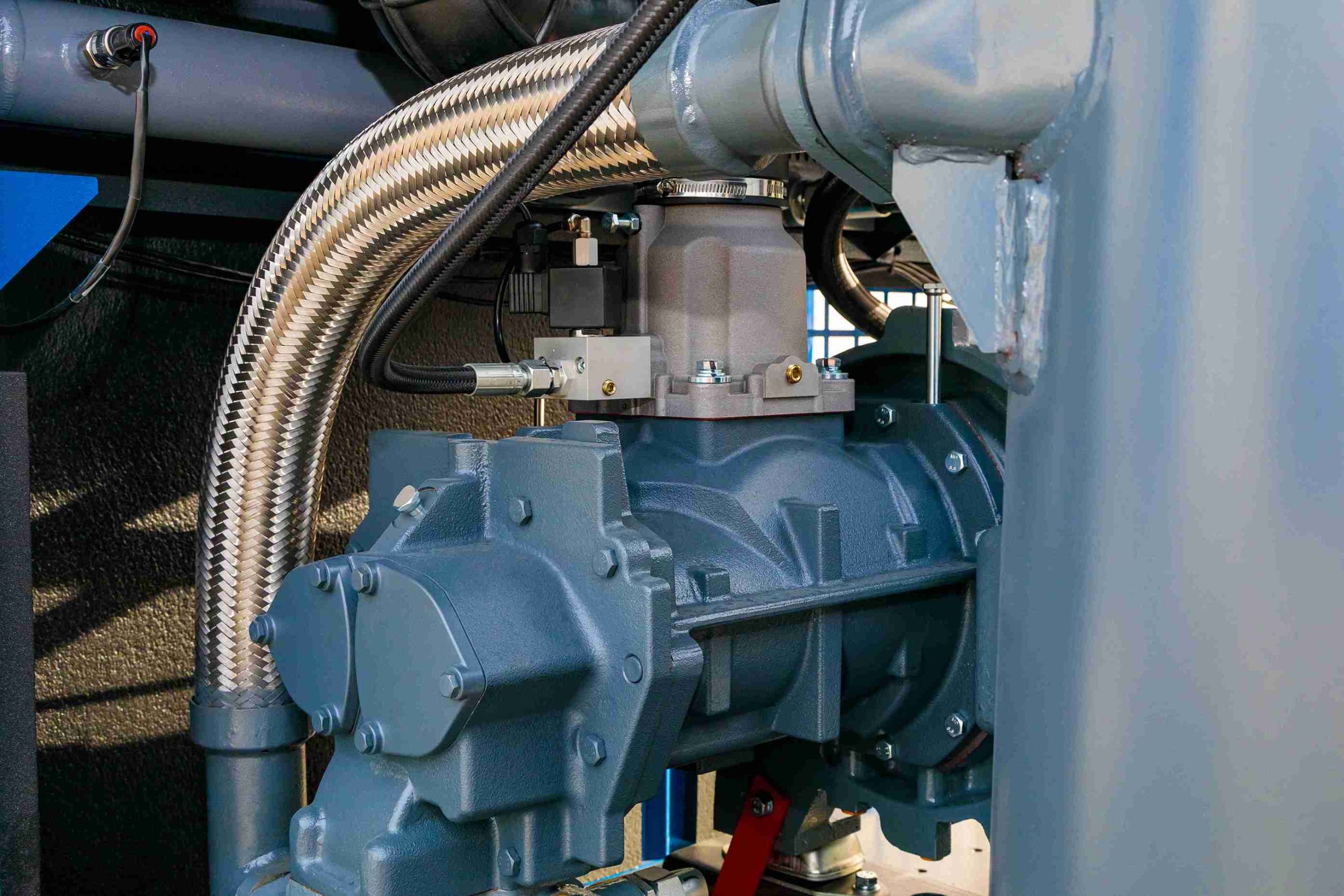

The operating principle of high-efficiency air-operated diaphragm pumps can be understood more clearly when we look at the key components that make up these modern machines. The accompanying diagram provides an overview of features typically found in these pumps:

– The diaphragm is a flexible membrane which can separate compressed air from incoming liquid and send it through to be pumped without leaking.

– Air Inlet The compressed air required for pumping oil into the pump comes from here.

– Fluid Inlet The source of fluid to be pumped into the pump is here.

– Check Valves This is where the fluid intake port has to be pumped into an outlet chamber for processing.

Operating Mechanism of High-Efficiency Air-Operated Diaphragm Pumps

When the air-operated diaphragm pump is initiated, compressed air is drawn into the air inlet, causing the diaphragm to flex and form a vacuum in the pump chamber. This vacuum sucks liquid from the fluid inlet into the pump. As the diaphragm returns to its original shape, liquid is expelled from the pump through the outlet.

The Stars and Uses of High-Efficiency Air-Operated Diaphragm Pumps

In the aluminium veneer production process, high-efficiency air-operated diaphragm pumps have several advantages:

Reliability: its rugged structure and consistent performance mean no downtime and no outages.

Versatility: with a broad range of fluids, they can be used in all kinds of applications in the production line.

In addition, the design features of high-efficiency air-operated diaphragm pumps reduce energy consumption while increasing output. This results in cost savings as well as raising efficiency.

Therefore, in aluminium veneer’s production process high-efficiency air-operated diaphragm pumps are a foundation for both external and internal applications. Their reliability, versatility, and high quality make them essential parts of contemporary industrial plants.

Air-Operated Diaphragm Pumps in Modern Aluminum Veneer Production Process

In modern aluminium veneer production, air-operated diaphragm pumps are involved in many essential jobs. They enable precise material transfer for both exterior and interior applications and are thus indispensable.

Pros of Air-Operated Diaphragm Pumps

When considering the use of air-operated diaphragm pumps in aluminium veneer-formed products, several advantages are evident:

| Pros of Air-Operated Diaphragm Pumps |

|---|

| 1. Versatility: These pumps can handle a large variety of materials, thus suit themselves to all stages in the production process of aluminium veneer. |

| 2. Resonance Start: With resonant start, the task of getting these pumps going is both quick and efficient, thus reduces downtime in productive runs. |

| 3. Flow Rates Variable: Operators can control the flow rates of air-operated diaphragm pumps. This allows them to meet the demands of many different operations in production. |

| 4. Resolute Build: A well thought-out design, the pumps can withstand being run in the most demanding surroundings. |

Installing air-operated diaphragm pumps

Incorporating air – operated diaphragm pumps into an aluminum veneer production process s essential to follow the steps below:

- Assessment of Material Compatibility: To ensure that the materials being transferred are compatible with the pump’s diaphragm material, so as to prevent erosion or damage.

- Installation and Setup: Correct installation and setup of the pumps are essential for obtaining their best performance. Place and connect them accor- ding to the manufacturer’s guidelines.

- Monitoring and Maintenance: Regular monitoring pump performance and scheduled maintenance both help prevent sudden shutdowns and guarantee uninterrupted production.

- Training and Safety: Operators should receive the necessary instruction and education in safe use and maintenance of air – operated diaphragm pumps, so that they can operate efficiently without danger in the production environment.

Utilizing these steps in conjunction with the advantages of air-operated diaphragm pumps, modern aluminum veneer production can achieve a higher degree of productivity and quality both in exterior and interior applications.

Benefits and Difficulties of Air-Operated Diaphragm Pumps

Prior to adopting air-operated diaphragm pumps in its external and internal aluminum veneer processing line, every project team must weigh the advantages with any problems or difficulties encountered. Let’s take a deep look at benefits and obstacles that might come up when you install these machines in your project.

Benefits of Air-Operated Diaphragm Pumps:

- Versatility: Air-operated diaphragm pumps are extremely versatile — They can handle materials with different viscosities across a broad spectrum. This versatility allows you to use the same pump for multiple applications, which in turn cuts down on the need for different pumping systems.

- Self-Priming: These pumps are self-priming, meaning they can still work effectively when there are no liquids in them. This feature makes setting up qnd running the pump easier to accomplish and also lowers the risk of damage from dry running.

No3: The diaphragm pump can handle abrasive viscous fluids, materials that may baffle other pumps. This combination of capabilities means smooth operation for even the most unyielding substance.

4 Maneuverability: Owing to its small, portable and air-powered design, a diaphragm pump can be positioned and moved freely. Fit one of these pumps in wherever it is needed at your plant or remote facility.

5 Design simplicity and ease of maintenance: When it comes to air-driven diaphragm pump design, simplicity is an advantage. Low servicing and repair significance, few complex components compared with say fraud probe pumps’ routine tasks are that much less complicated shortening downtime and overall cost of maintenance.Air usage: With air-operated diaphragm pumps, one big issue is how much more they consume than most pumps. And because it takes in more air at the same time, this increased amount of air can quickly drive operational costs even higher-especially when they are run continuously or if three machines must all be running together for long periods.

Pulsation: With a pulsating flow, an air-operated diaphragm pump’s action inevitably disturbs any fragile balance. This may be an unacceptable-state-of-affair: In such cases additional measures are required to cure these pulsating effects as they unavoidably appear in various production processes.

Diaphragm life: The diaphragm in these pumps will experience wear and tear from working continuously or when it comes into contact with abrasives over time. Regularly replacing these diaphragms – something that is not mentioned enough in general literature on pump maintenance – is very important for maintaining optimal pump functioning without leaks to slow you down just at those critical moments when you need them most.

Noise**: Air-operated diaphragm pumps are very noisy, even so much so that in some instances this noise cannot be tolerated. Sound insulation measures and putting them in isolated areas will help to solve the problem of noise pollution.

In sum, whereas air-operated diaphragm pumps have such potential virtues as diversity, self-priming, and the suitability of materials for pumping, they also incur air consumption (and the subsequent costs), pulsation, diaphragm wear problems, and noise issues. Thus, with careful thought you can conclude if these are the right pumps for your aluminum veneer production system.

Best Practices for Maintaining and Optimizing Air-Operated Diaphragm PumpsIf you want your air-operated diaphragm pumps to work longer and better, it is essential to follow best practices in maintenance and optimization. By carrying out these strategies effectively, you will ensure that you can maximize your pumps’ performance while also bringing down the frequency of their breakdowns; essentially allowing them not any real time ’off the job.’ The following are some key practices which may prove very worthwhile for those with air-operated diaphragm pumps. Consider them carefully:

Regular Inspection and Cleaning

In conclusion, whereas air-operated diaphragm pumps have such virtues as versatility, self-priming qualities, and a wide range of materials for pumping, the cost of air consumption which follows on from this leads to problems. Also these pumps produce pulsation, they are subject to diaphragm wear (abrasives again) after just three months: Since you have to keep checking the diaphragms for bulges instead of relying upon scheduled replacement-and noisy too explains Kirkland therefore must either be installed in sound-isolated areas or one can take steps towards soundproofing them.

Table 1: Maintenance Schedule

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Diaphragm Replacement | Every 6 months |

| Valve Cleaning | Monthly |

It is very important to conduct regular inspection, if you can find early wear or damage, you can solve it right away. And do not forget to clean the components such as valves and diaphragms to avoid clogs in case of any downtime.

Proper Lubrication

- Table 2: Recommended Lubricants

| Component | Type of Lubricant |

|---|---|

| Diaphragm | PTFE-based grease |

| Air Valve | Silicone oil |

| Pump Housing Seals | Mineral oil |

Using appropriate lubricants for different components aims to reduce friction, increase longevity and improve parts performance.

Monitoring Air Pressure and Flow Rates

Regularly monitor The air pressure and flow rate,help to discover any non-standard conditions.which may have developed in the course of operation. Adjusting these parameters accordingly can ensure an overload-free pump and that it runs efficiently.

Training and Education

In order to extend the life of air-operated diaphragm pumps, providing training for operators on their proper use and maintenance is crucial. Rather than lamenting an unplanned shutdown due to neglect, educate staff in best practices of plant operational management.

So supposing you follow these best practices for maintaining and optimizing air-operated diaphragm pumps, you can reduce the number of problems in your aluminum veneer factory bring upon yourself. Your equipment will come to a high degree reliable and efficient, and this in turn,lead to more output in factory with less costs.

Comparison: Air-operated Diaphragm vs. Traditional Pumping SystemsAdvantages of Air-Operated Diaphragm Pumps in Aluminum Veneer Production

When we consider the benefits of air-operated diaphragm pumps in aluminum veneer production several key advantages stand out. Some of these include:

1 Versatility in handling all kinds of liquids;

2 Self-priming capabilities which raise its efficiency;

3 A vast range of high-viscosity fluids can be handled by just one pump;

4 Intrinsically safe for operation- AOD pumps are;

5 Minimal maintenance requirements;

6 For abrasive and shear-sensitive materials, it has its uses for surface treatment and other applications.

Conclusion

- High-efficiency air-operated diaphragm pumps play a crucial role in modern aluminum veneer production, ensuring smooth and reliable operations.

- The use of air-operated diaphragm pumps contributes to the overall engineering elegance of the production process, combining efficiency with precision.

- This form of pump helps manufacturers keep a consistent quality during the production of both the exterior and interior aluminum veneer

- The all-round operation of air-operated diaphragm pumps will also bring higher productivity at every stage in production

- Choose high-quality air-operated diaphragm pumps as your best bet for processing aluminum veneer. It is cost-effective and will ensure long-term benefits.